Get the latest climate technology news directly to your inbox.

Building a supply chain for rare earth elements

China’s ban on the export of key technologies raises alarms about the supply of rare earth elements, which are used in EVs, turbines, and other electronics.

Rare earth elements (REEs) are essential ingredients in electric vehicles, wind turbines, and many electronics. As with most critical minerals, China controls the vast majority of the REE supply chain. And so when it banned the export of REE processing technology last December, it raised concerns about supply.

So what will it take to secure the supply of REEs?

In this episode, Shayle talks to Ahmad Ghahreman, CEO and cofounder of Cyclic Materials, a rare earth elements recycling company. (Energy Impact Partners, where Shayle is a partner, invests in Cyclic.) They cover topics like:

- The five high-value REEs used in the permanent magnets inside EVs, wind turbines, and electronics

- The many steps in the supply chain, from extraction to end-of-life

- Building magnets without REEs

- Increasing production outside of China

- The role of recycling

- Why Ahmad is optimistic about developing a supply chain in North America

Recommended resources

- MIT Technology Review: The race to produce rare earth elements

- IEEE Spectrum: Who Will Free EV Motors from the Rare Earth Monopoly?

Transcript

Announcer: Latitude Media, podcasts at the frontier of climate technology.

Shayle Kann: I'm Shayle Kann and this is Catalyst.

Ahmad Ghahreman: I believe that access to mining and downstream capacity in North America, engineers will sell really like rare earth magnets and buyers also will like rare earth magnets because they have multiple options for sourcing of rare earth magnets now. I'm really optimistic on the domestic supply of rare earth magnets.

Shayle Kann: Well, for all those listeners who've been patiently waiting for a podcast on neodymium, I just want to tell you that I hear you, I see you and today's your day.

I'm Shayle Kann. I invest in revolutionary climate technologies and energy impact partners. Welcome. Well, I've been known to say that the energy transition is at least to a first order, basically a transition from fossil fuels to metals and minerals. We've talked about some of these winners of this shift here before battery metals like lithium, nickel, cobalt, as well as other critical minerals like copper. I'd say there are two common themes amongst those discussions. First, we're going to need a hell of a lot more of each of these things as we go from early adopter of decarbonized technologies to the majority. And second, there's pretty much always a complex geopolitical challenge that we face in that transition, whether it's the Democratic Republic of the Congo for cobalt or South America for lithium and copper, Indonesia for nickel.

Then there's China, always China. Nowhere are both of these issues actually more prevalent than with rare earth elements. The story there is playing out in real time. Demand is growing as it is with many of these other elements. Supply is a challenge and it still largely does come from China, which has just recently actually a few months ago, instituted a ban on the export of new technologies for extraction and separation of rare earth elements. The whole area is vitally important and very complex. We at EIP have been on a critical minerals and metals kick for a couple of years now, which has resulted in multiple investments to try to solve some of these problems. One of those investments was Cyclic Materials whose founder Ahmad Ghahreman is my guest today.

We co-led Cyclic Series A financing last year alongside BMW Ventures. Today Ahmad and I talked about Cyclic, but also just as importantly talked about the big picture challenge of securing enough rare earth elements supply during the energy transition. Here's Ahmad. Ahmad, welcome.

Ahmad Ghahreman: Thank you for having me.

Shayle Kann: Excited to have you and to talk about rare earth elements. Starting with the definition, what are rare earth's elements? This is actually something that I think probably our listeners appreciate, but I've found a lot of people in the broader public, they hear rare earths and they think of things like lithium and cobalt and other stuff that are not actually rare earth elements. So what are rare earth elements?

Ahmad Ghahreman: Great question. Lithium and rare earth elements and some other metals are in a category called critical metals, and that's probably the times that I see people confuse rare earth elements with other elements. Rare earth elements are a group of metals at the bottom of periodic table, and of course you can graduate high school and not learn about them. These metals are 15 plus two, so overall 17 elements. Because of their chemical and physical properties, nowadays we have a lot of applications for them in different sectors, especially back to energy transition. Those are your rare elements.

Shayle Kann: You said there's 17 of them. Are current uses of rare earth elements pretty evenly spread across the 17 or most of the 17, or are there a few that are dominant where we really use a lot of whatever, neodymium or dysprosium but not a bunch of the other ones? Separate them out from each other a little bit for me.

Ahmad Ghahreman: Absolutely. Out of 17 rare earth elements, there are five of them, sometimes six of them that we call them magnet rare earth elements. Let's take a step back. Rare earth elements are used in variety of applications and catalysts and glass and different applications alongside magnets. We use them in permanent magnets. Happens that when we use rare earth elements in permanent magnets, which we call them rare earth permanent magnets, those happen to become the most strong magnets that we can make on our planet. This is really unique to reverse magnets.

From a volume side, the five or six rare earth elements that we use in permanent magnet manufacturing, accounts for about 40% of rare earth elements. 40% of rare earth elements go into magnets, the other 60% does not. But here's the interesting thing. From dollar value perspective, over 95% of rare earth elements are the five that we use in permanent magnets. And the combined 60% of rare earth elements carry only less than 5% of the dollar value in the market for rare earth elements. You can see how valuable permanent magnet rare earth elements are, which are subcategory of rare elements.

Shayle Kann: And which ones are those?

Ahmad Ghahreman: Oh, those are neodymium, praseodymium, dysprosium, terbium and samarium. Nowadays, we mix a lot of samarium into magnets as well. Now neodymium and praseodymium are among the light rare earth elements and those are basically the very important ingredients of permanent magnets. Dysprosium and terbium, we use them in tiny little bit concentrations in magnets to give them really high temperature, good quality magnets that we use in electric vehicles and some other applications.

Shayle Kann: This is one thing I've always wondered, we're going to talk a little bit later about do we really need the rare earth elements? Can we displace them with something else? We will focus probably on this permanent magnet thing, because that's the most relevant to the energy transition, as you said, it's where the vast majority of the dollar value is. Why is it that this basket of rare earth elements makes permanent magnets so much stronger? What is it about them that enables that?

Ahmad Ghahreman: Oh, it's their physical and chemical properties. It happens that when you combine neodymium, praseodymium with iron and boron with very specific physical properties that they have and they carry, you end up with really strong magnets that has significant energy density in a small volume. That is the differentiator of these type of magnets versus magnets versus other magnets in the market. We count on this property of rare earth permanent magnets significantly in the energy transition.

Simply put, those permanent magnets. Now from the application side, one of the areas that we use them very often is when we want to convert electrical energy into mechanical energy from a battery to driving a car, or the other way around from mechanical energy to electrical energy in a wind turbine generator. When we use rare earth permanent magnets, we happen to make the most efficient electric motors or generators out there that we know of. If you are putting a lot of dollars into a battery pack in an EV, it just makes sense to tie it up to a very efficient electric motor and consume that electricity efficiently. When you think of systems, then using permanent magnet electric motors becomes really important.

Shayle Kann: That speaks to why not only do we use a fair amount of rare earth elements already today, but the expected trajectory follows the expected trajectory of the energy transition, primarily in things like electric vehicle adoption, to some extent wind turbine development as well. Now we're back in the category with some of the other energy transition metals, as you said, like lithium, cobalt, nickel and so on, where there's this secular growth trend in demand. We'll come back to demand. I want to talk about supply. Let's start with where we get rare earths from. When there's virgin mining today, where are the rare earths in the world? Then walk me through the supply chain as it exists today.

Ahmad Ghahreman: Sure, absolutely. Two things. If it doesn't grow, you mine it. We start with mining. The second thing, rare elements are recycled less than 1% globally. Those are among the least circular metals that we know of out there. Basically, the primary source of rare earth elements today is mining of rare earth elements. About 60% of that happens in China, and the other 40% give or take is happening outside in other countries, including the US. Now that's 60% in China, some of that is byproduct of iron oxide mining as well, but overall majority of mining happening in China.

It happens that in the downstream processing though, majority of those mined materials outside China are shipped to China. So China acts really like a vacuum here, brings in all the material to China and processes and produces magnets. The processing is over 90% done in China and magnet manufacturing over 95% done in China. From there it's shipped around in final products in electric motors and other units for consumption all over the world.

Shayle Kann: It's true in a number of these categories in critical minerals and metals, that China has found itself in a pretty dominant position with regard to processing and refining. It's especially dominant in rare earth elements and in permanent magnets. But that is true in lots of different categories. What is interesting though, is that China is also the home to the majority of the mining in rare earths, which is not true of all these other categories. You look at something like lithium. The mining takes place in South America or in Australia, and then a lot of the refining takes place in China. Is the reason that China is dominant on the mining side because the resource happens to be in China, or is it just that China put more effort and investment into building a rare earth mining industry or as you said, a byproduct of iron mining than other countries have?

Ahmad Ghahreman: The combination of both. In Canada and US in 1960s and '70's, the US and Canada used to be a leader in production of rare earth elements. Significant production of rare earth elements from mining side was done in other countries as well, outside China. Mining of rare earth elements comes with some unique challenges. For instance, radioactivity of ores that come off the mines usually is one of the challenges that radioactive materials are from concentration perspective high enough that they cause really environmental problem on that side, but low enough that they can't be economically recovered from the material. Things like that over the time basically put pressure on mining of those metals outside China and North America specifically, and those eventually ended up in China. China gradually picked up on production and mining of those metals, as well as the other environmental impacts.

After mining, when you have the ore or concentrate that comes of the mine, usually the chemical process that you would require to put the material through to get to the metals at the back end is pretty environmentally, I'm going to say, challenging process. When you have that in North America, it's basically not ideal. We shipped those processing capacity in the past 20, 30 years to China, and all of a sudden we woke up and they had all the production capacity within Chinese borders. That happened mostly for rare earth's elements from mining all the way downstream.

But as you said, for some other metals, they really heavily invested in downstream processing of copper, downstream processing of other metals like cobalt, like graphite, like lithium. That basically all of a sudden gave them a lot of advantages over production of downstream products. Whereas in US, we don't have much of those metals available today to build the plants. This is interesting to note also that, rare earth's elements on themselves are about in 2024, $20 billion market. But the downstream or the industry they unlock is in trillions of dollars. I think at some point we did a miscalculation on the priority of how important these metals are in North America. To be frank, China has been publishing their five-year plans every five years in the past 20, 25 years, and they constantly said, "We want these metals in China," and here we are, they have it in China.

Shayle Kann: We'll come back in a few minutes to what are the solutions to this geopolitical challenge that we face. But first, can you walk through the steps from raw ore mining to a magnet that goes into a motor that goes into a vehicle. What are the steps along that process?

Ahmad Ghahreman: It starts with mining. You produce... Well, you mine the ore. Again, majority of that happens in China, to some extent that happens in California as well by MP Materials. The next is to take the ore which has only one or 2% rare earth element in it, sometimes even less than that, to a product that is called concentrate. Now concentrate usually has 50, 60% rare earth oxide value in it, and that also is quite a bit produced in China and a little bit outside China as well. Now majority of concentrates now are being shipped to China. When it comes to processing now, give or take 90% of concentrates are processed in China. In this process, basically you take the concentrate and with very heavy chemical process drive it all the way to now called mixed rare earth oxide, which is a basket of rare earth elements that comes off as a final product from the concentrate.

Now, mixed rare earth oxide really depends. The quality of mixed rare earth oxide in each plant or each deposit will depend on the ore that they processed. For instance, for the material from California that is shipped to China, usually you end up with about 70 to 80% of lanthanum and cerium oxide. Those are the metals that don't carry much value. This number will be different in other mixed rare earth oxides that come of other deposits, but universally 70, 80, 85% of rare earth oxides are going to be negative value rare earth oxides in those mixed rare earth oxide baskets. For Cyclic Materials, for us it's different because we recycle only magnet metals. I'm going to come back to that.

Shayle Kann: That's a key point though, and it's part of why I wanted to ask it the beginning about separating out the different rare earth elements from each other. Because you could think of them as one basket, but actually what's interesting about the process as it exist today as you just described, is that you mine an ore, you concentrate the ore, then you process it, you get this basket of things. Whereas with lithium, lithium is lithium, but in rare earth elements, what you're getting is a basket of rare earth elements, even after you've gone through your processing step. As you just said, the majority of what is inside that basket is actually negative value. What you really want is the minority of what's inside that basket you've already processed, which is mostly just those five to seven rare earth elements that we actually care about.

Ahmad Ghahreman: Absolutely. Then again, those mixed rare earth oxide now have to go through the process of refining. That's basically a long chain of solvent extraction unit operations, usually done in 1000 or so steps, sometimes even more to separate rare earth elements, each of those into an individual basket. Now, you have pure cerium oxide, you have pure neodymium oxide, you have pure dysprosium oxide, some of those are mixed together, for instance, NDPR and whatnot.

Now, solvent extraction has been around for many, many years. The reason solvent extraction or refining for rare earth elements is really complicated, is because the chemistry of each individual rare earth elements out of the 17 is pretty similar to one another. So you are now separating metals that they behave pretty similar in the process with one another. That's why the efficiency of process is really low, so a long chain of solvent extraction happens to do so. This is pretty expensive process as well and produces a lot of waste simply because, let's say it again, around 80% of your rare earth elements in mining industry, our value negative rare earth elements that we way overproduced those, so hence they are value negative.

Now after you produce individual rare earth oxides with high quality, then the next step is to metalize those. You make metal out of those oxides, you basically remove the oxygen and you make metals. In this step, basically 95% of the process is being done only in China. We don't have much metalization industry outside China, simply because the oxides are not available outside China. The next step is basically magnet companies will take those alloys of magnet after metalization and they grind or cut out the magnet pieces that they need in the size and shape that they need, and then they insert it into the electric motors, and then you have your electric motor for electric vehicles or other applications. That's basically as close as to a product you get. Then the next step is to ship that product into the market.

Shayle Kann: Okay. That's the process that exists today. Before we talk about what to do about it, actually I want to go back to the geopolitics for one second, because as we've said multiple times, China is pretty dominant here. Trade tensions between China and the western world have been high of late and that has trickled down into rare earth world. What's the latest on China export curbs in rare earths and what are we to make of it?

Ahmad Ghahreman: One thing that we really were expecting to happen a few years ago happened last December, China put a pause on exporting of any technology related to rare earth elements, mining and recycling and processing. That's really important to understand, simply because they are trying to maintain their dominance in this space and not give it away. At the same time, to counterbalance that, we have IRA and other vehicles in North America, Europe, and other jurisdictions to help industries to grow in those countries.

For instance, Department of Defense awarded Lynas in Texas us with over $200 million to build capacity on refining of mixed rare earth oxides or Department of Defense awarded over $100 million dollars to Vacuumschmelze, a magnet manufacturing company to build their facility in South Carolina, which we have partnered with them. There's a lot of efforts in this space happening to reduce the dominance and dependence of rare earth elements supply chain with China. I am really optimistic on this side, because those efforts I really think this time around are being done really nicely and the right way they should be done. But still in 2024, we are heavily dependent on China on sourcing of those materials.

Shayle Kann: Let's talk about what to do about it. I think of it is being three categories of things that you can do about it, and we're going to save the one that you do, which is recycling for last. But the three categories in my mind are first we could change the demand picture. Now I don't think that's going to be changing the demand picture by reducing demand for electric vehicles. I think it would have to be magnets, permanent magnets that do not require rare earth elements or that require less of them. That's one category.

Second category would be just ramp up our supply of virgin mining and processing outside of China in the western world in various places. As you said, there's some of that already, particularly on the mining side in California, you just do a lot more of that. Then the third is recycling, which we'll save for the end because that's where you're focused. But let's talk about those first two first. What have you seen out there in terms of developments to try to make rare earth elements less necessary if we are building permanent magnets?

Ahmad Ghahreman: Sure. Let's start with rare-earth-free magnets, because there is a conversation going on on that and some companies are looking into design of rare-earth-free magnets. Just to be clear, rare-earth-free magnets do exist today. Alnico group of magnets and Ferrite group of magnets are already out there. The industry wants to create newer category of rare-earth-free magnets that possibly they could use in substitution to rare earth permanent magnets in electric vehicles, wind turbines and other applications. I don't believe we are there yet, but out of necessity, I believe this is the right step to take. Some of those magnets already are being produced by some companies out there and in the US as well.

It appears that some of those magnets eventually will be consumed in speakers industry and other similar industries. Again, the majority of drive of rare earth element consumption, especially on the magnet side, are going to come from wind turbines, from electric vehicles and some other applications that speakers are a small portion of that. We still will have the demand for rare earth's permanent magnets out there in the next years to come. I haven't seen a solution to that just yet.

Shayle Kann: Is that because, as you said at the beginning, the reason rare earth elements are so valuable in a magnet is they make the magnet stronger. Is it true that the applications where these rare-earth-free permanent magnets make the most sense, are the applications where the requirement for magnet strength is lower and that's what's true about speakers, for example, but not as true about wind turbines and electric vehicle motors?

Ahmad Ghahreman: Correct. How strong the magnets are per unit of volume, that's one indication for quality of the magnet. The second one is at high temperature they still remain magnetic, so they don't lose their magnetic properties at elevated temperatures. Now when you have a speaker, usually is at room temperature, maybe a little bit elevated temperature, but when you have a traction motor of an electric vehicle because of the rotation, usually have heat in there, so that's a little bit different game in there. Those qualities and the energy density in the magnet basically are the reasons that some of those magnets haven't found use in high-end applications in industry just yet.

Shayle Kann: Okay. All right, so substitution may play a role eventually, kind of hard to tell. Technology is not quite there yet, but you could imagine that. A second option is just ramping up supply x China, what do you see happening there? That's supply both from a mining perspective and then obviously equally importantly, from a processing and refining perspective.

Ahmad Ghahreman: This is where I'm quite a bit optimistic. For instance, mining industry in US and other jurisdictions are looking into extraction and processing of various elements. For instance, MP Materials in past few years have shown that they can basically mine and ship the material to China and process it in China. There is already one step of the process completed in the US, now they're looking into downstream to bring the processing back to us and process the material up until production of magnet through MP Materials. They have been having some press releases on that side in the past few months and making advancements on production of magnet and also production of high quality neodymium, praseodymium and US on that side as well. I think mining and processing is the area that we have spent a lot of money in North America and Europe of course on it as well and eventually will come very handy.

Simply put on the mining side, we have resources out there that are producing concentrate today, so that's good. On a refining side, for instance, Lynas that already is refining in Malaysia, is building a plant in Texas. That's another really strong indication that very, very likely we will have refining capacity in the US as well. On magnet manufacturing side, also companies like Vacuumschmelze which have years of experience in manufacturing high-quality magnets are starting to build capacity in North America as well. From that perspective, I'm really optimistic.

Now today when it comes to consumption of magnet and the companies, let's say OEMs, car manufacturers, there are two stakeholders in there, engineers, they love rarest magnets, they can't get enough rare earth magnets actually. The second stakeholders are buyers and OEMs, and they dislike rare earth magnets because their supply chain is heavily associated with one country. Now fast-forward a few years, I believe with access to mining and downstream capacity in North America, engineers will still really like rare earth magnets and buyers also will like rare earth magnets because they have multiple options for sourcing of rare earth magnets now. So I'm really optimistic on domestic supply of rare earth magnets.

Shayle Kann: That brings us to category three, the category that Cyclic is focused on, which is recycling. You said before that we only recycle 1% of rare earth today, which anybody who knows something about lots of other commodity metal industries like copper and steel and so on, we recycle a fair amount of all those things. Why is it that we don't recycle rare earth today? And then obviously that will dovetail into what are you doing about it?

Ahmad Ghahreman: Absolutely. Yes, true. Rare earth elements, which actually when department of energy looks into critical metals, categorizes them as the most critical metals in the category of how critical those are. Happens to be the least circular metals as well, so we don't recycle much of those at all today. Simply because when we recycle end-of-life products, the magnets being magnetic, attach to steel and travel with steel into steel recycling plants, iron recycling plants. Because of the chemistry in the steel recycling plants, rare earth elements report to a phase or chemistry and steel production plant that is called slag. It's a glass, just looks like glass on our windows really, and rare earth elements are locked inside the glass for good forever, and thermodynamically really stable and you can spend a lot of money recycle those and recover those, but that would not make you money and would be very environmentally polluted as well. That's the main reason why we don't recycle rare earth elements today because we lose them into steel recycling plants.

Shayle Kann: Right. It's the process of steel recycling that locks the rare earths away permanently, because they end up in the steel slag and as you said, extremely thermodynamically stable. You theoretically could get the rare earths out of there, but it would come at such an energy penalty, it would never be worth it.

Ahmad Ghahreman: Correct. It would be very expensive and environmentally harmful.

Shayle Kann: Right. Okay, so how do we solve that?

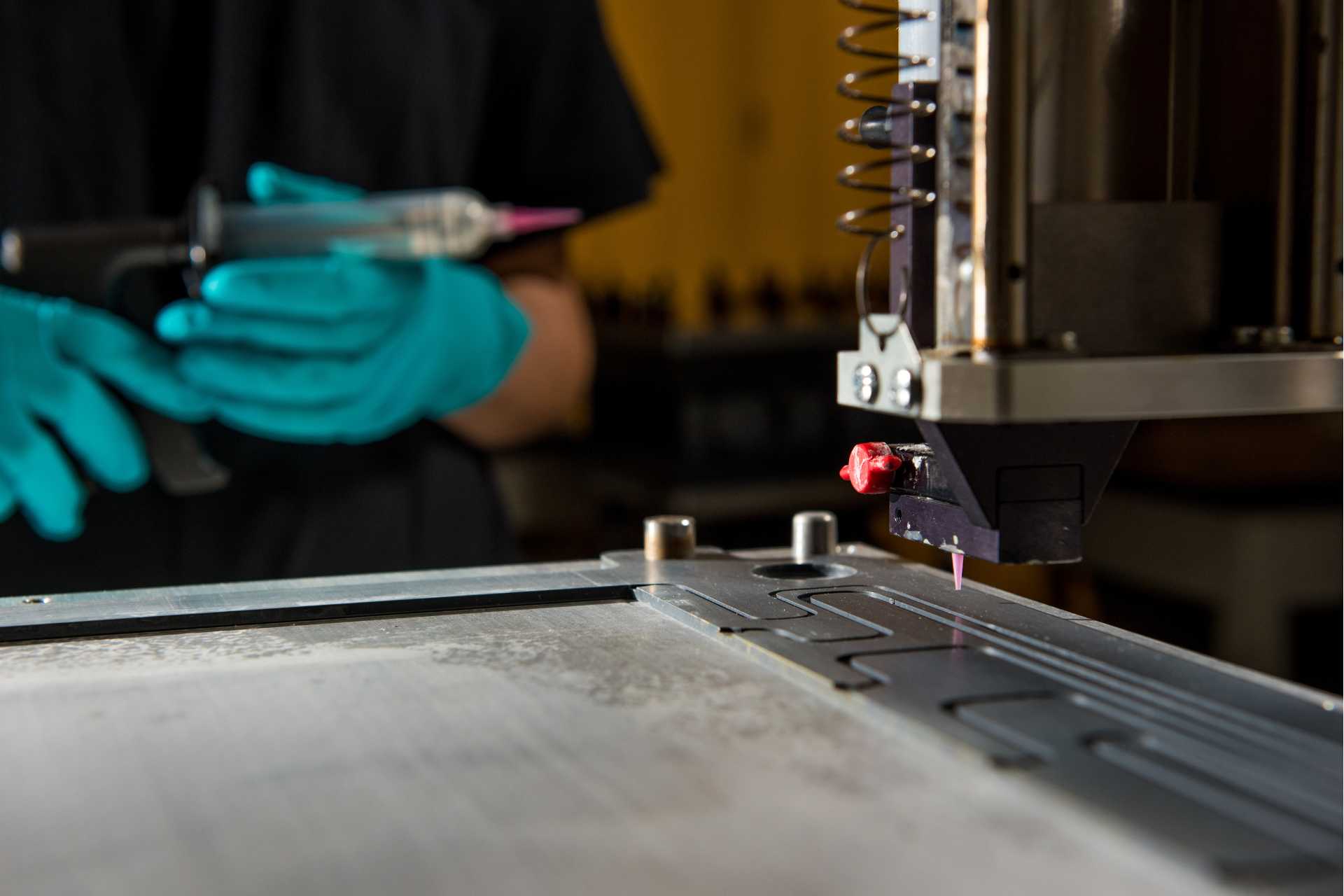

Ahmad Ghahreman: We do have two set of technologies in our company. The first technology basically in our spoke operations separates magnet from everything else. Imagine a traction motor of an electric vehicle comes in, we separate copper, aluminum, steel and magnet into four different buckets. Now, copper, steel, aluminum, they already are known in the market how to treat those, so we sell those off. Magnet, we hold onto it, we send it to a secondary operation or technology that we have in the company, which is the core. The technology is the core of our hub operation now. We have spoken hub model. Our hub, magnets would come in and with hydrometallurgy process we would basically process those magnets and we produce mixed rare earth of oxide. Now, I will point out that our mixed rare earth oxide is one of the highest quality mixed rare earth oxide today available in the market actually, simply because it's gets purely concentrated with magnet rare earth metals.

Shayle Kann: Right. The other way to put that is, that if you're mining an ore, you're getting a bunch of rare earths out with no regard from the ore body as to whether those are the ones that we humans happen to care about or not. Whereas if you're recycling, you are starting with only the stuff that we used in the first place.

Ahmad Ghahreman: Hundred percent. But above that, when you mine rare earth elements, very, very often in majority of cases you have some radioactive materials to treat as well. But in recycling, because we recycle end of life products that already have been refined, we have no radioactivity in our operations because nothing comes as a feed to our processing plants.

Shayle Kann: Okay. Cyclics process, as you said, is two steps. Step one, you remove the magnet from the steel, and obviously from the other things as well, which you can sell off as commodity metals like copper. Step two, you take that magnet, you send it to a central processing facility, that processing facility gets you your basket of rare earths, mixed rare earth oxides, out of the magnet. I guess the question is, why two steps? You're doing this hub and spoke model, why is that the right way to run this kind of recycling operation?

Ahmad Ghahreman: Great question. We do recycle end of life products that carry magnet. End of life products consumed by human have really large entropy, meaning that they are distributed on our planet very, where we have more population, where we'll have more of those end of life products. In recycling business, one of your key elements to optimize for is your logistics and shipping and handling costs. We would like to be closer to our feedstock sources. From that perspective, having a [inaudible 00:33:26], for instance in North America, spokes will make sense. We would be closer to the centers where those end of life products are available, we will process those.

Simply put, iron, aluminum and copper have large market with distributed market all over the planet so you can tap into that market. But magnets, which are less than 5% of feed that comes to a spoke, could be shipped to a central plant. For whole North America, you could have one central plant, one hub and process the magnets in there and produce the rare earth oxide in there. That would give you the optimum operating costs on the spoke side and bringing in feedstock and also optimum capital costs on the chemical plant having just one central location to do so.

Shayle Kann: One of the questions that gets asked a lot in the context of battery recycling is, what portion of global demand could recycling actually supply? Battery recycling people say, "If we recycle all the batteries that are available to us and in some future state we don't need to mine so much virgin lithium, nickel, cobalt, graphite, et cetera." What is that in the context of rare earths? What portion of global rare earth element demand do you think could be met by recycling and when?

Ahmad Ghahreman: When it comes to other metals like copper, aluminum, steel, we recycle, give or take 40 to 50% of those metals. Even for metals that we produce a little bit of those like germanium and others, we recycle about 50% of those metals as well. When it comes to rare earth elements, we are doing really a poor job these days at around 1% recycling. I believe rare elements also could be recycled at around 40, 45%, 50%. There is a significant market possibility opportunity out there for rare earth recycling.

Cyclic Materials plan is by 2030, '31, '32, we will be recycling around 2% of the world rare earth elements. Also, our vision is that rare earth elements recycling is not a substitute to mining, it's just to reduce the pressure on mining. Also, when you recycle rarest elements from environmental standpoint, you produce far less carbon dioxide, you consume a fraction of the water that mining industry consumes to produce the same amount of product. From those instances also, we really need more and more of rarest recycling, but because of the increase and consumption of the metals in the industry, we can't really just rely on recycling and we will need a combination of healthy recycling and strong mining operations as well.

Shayle Kann: All right, Ahmad, this was enlightening. Thank you for your time. We obviously wish you the best and wish the industry the best at figuring out how to develop a geopolitically secure and clean rare earth supply chain.

Ahmad Ghahreman: Thank you so much.

Shayle Kann: Ahmad Ghahreman is the CEO and Co-founder of Cyclic Materials. This show is a production of Latitude Media. You can head over to Latitudemedia.com for links to today's topics. Latitude is supported by Prelude Ventures. Prelude backs visionaries accelerating climate innovation that will reshape the global economy for the betterment of people and planet. Learn more at preludeventures.com. This episode was produced by Daniel Waldorf. Mixing by Roy Campanella and Sean Marquand, theme song by Sean Marquand. I'm Shayle Kann and this is Catalyst.