Get the latest climate technology news directly to your inbox.

Why hourly matching for green hydrogen is no simple fix

Breaking down the vigorous debate over Treasury's proposed 45V tax credit guidance

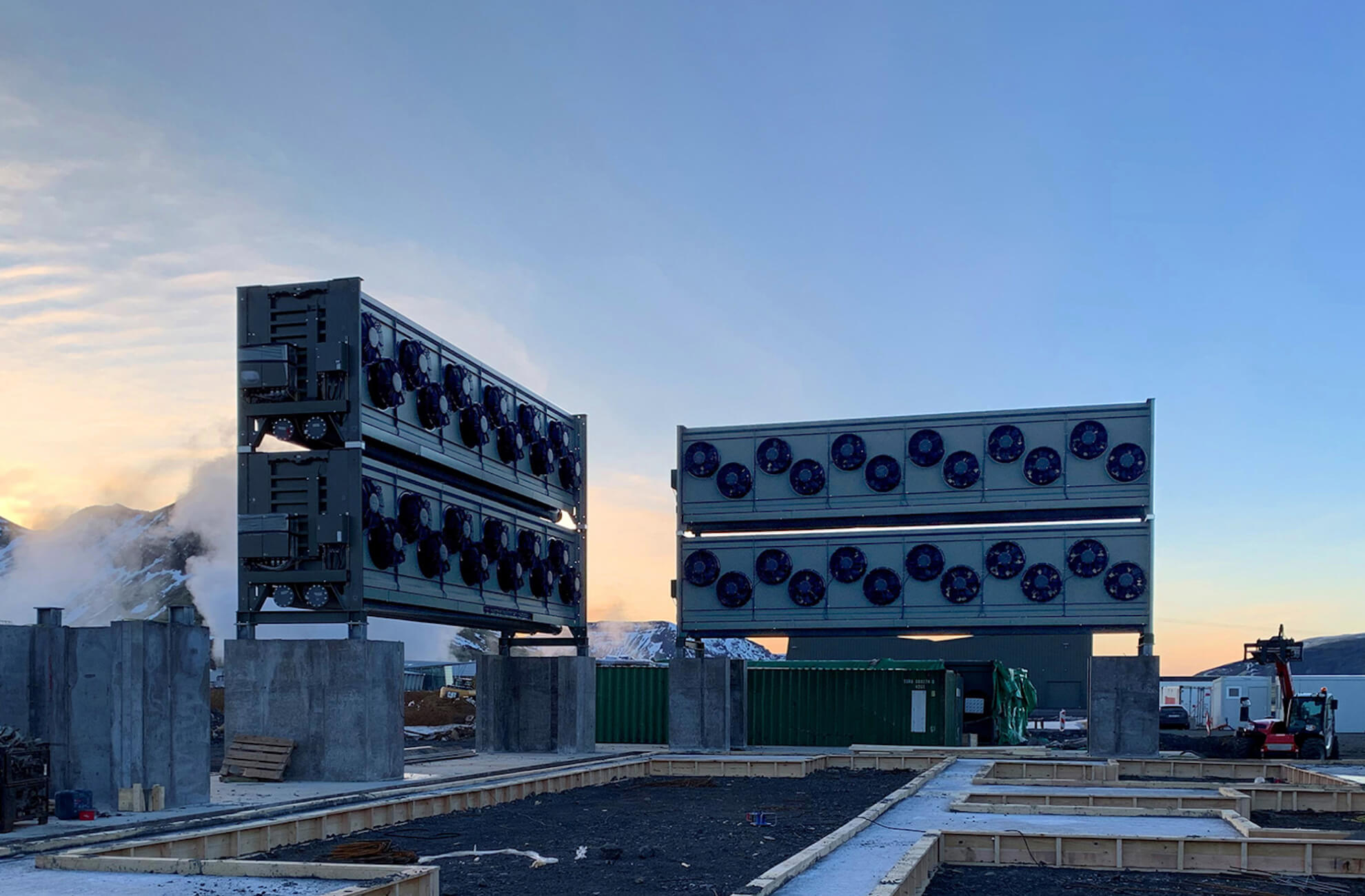

Photo credit: Ina Fassbender / AFP via Getty Images

Photo credit: Ina Fassbender / AFP via Getty Images

Two industries use practically all the hydrogen produced in the United States today: petroleum refining (57%) and the production of ammonia and methanol for fertilizer and solvents (38%).

And virtually all of this hydrogen currently comes from natural gas. Companies essentially crack open methane molecules, take the hydrogen, and vent the carbon dioxide into the atmosphere.

Unfortunately, as the Department of Energy’s National Clean Hydrogen Strategy and Roadmap notes, such gray hydrogen production in the U.S. currently emits greenhouse gasses equivalent to about 100 million metric tons of carbon dioxide each year. That’s roughly 2% of the country’s total yearly emissions.

Green hydrogen, on the other hand, is made by splitting a water molecule into hydrogen and oxygen, using clean electricity. No carbon is used in the process, and the only byproduct is oxygen — and no one is complaining that there’s too much oxygen in the atmosphere.

But getting the country’s many gray hydrogen users to make the switch to green is a complex proposition. Their industries are under tight margins and most lack a regulatory incentive to decarbonize their operations. For green hydrogen to start replacing gray in the near-term, we need to get green a whole lot closer in price to gray.

Studies from Wood Mackenzie have found that the cost of producing hydrogen and delivering it to the customer would need to be less than $2 per kilogram to encourage these sectors to switch.

The tax credit in the Inflation Reduction Act, offering $3 per kilogram of clean hydrogen produced, is certainly a positive step. As more renewable energy is added to the U.S. grid, clean electricity prices are expected to continue falling. And as electrolyzer production scales up, capital costs for green hydrogen projects will come down.

That trend could allow green hydrogen to eventually beat gray hydrogen on price, even once the tax credit ends. That would truly be a game-changing moment, because there would be no excuses left — companies continuing to make hydrogen from natural gas wouldn’t be as profitable as their green counterparts.

But now we get to the tricky part. The IRS rulemaking has become an unusually hot topic after the department issued draft regulations for the clean hydrogen tax credit created under section 45V of the IRA. During the written comment period, the IRS received 30,032 comments from a range of stakeholders. A public hearing was held on March 25 to take additional comments.

The roiling debate is focused on the adoption of a “three pillars” approach to ensure that green hydrogen production doesn’t lead to increased carbon emissions. It says that the renewable energy credits a green hydrogen producer buys should be deliverable (meaning the electrolyzer used should be connected to the same grid as the renewables it relies upon), incremental (using new or recently built renewables), and time-matched (generated in the same time-period as the energy is used).

There’s broad agreement that these three pillars are necessary to ensure the credibility of green hydrogen as a decarbonization pathway. The devil is in the details, though, particularly when it comes to the time matching requirement.

Under the proposed rules, green hydrogen producers will need to purchase renewable electricity credits in order to run their electrolyzers. After 2028, these “Energy Attribute Certificate” credits would need to be matched hourly with electrolyzer power consumption.

Many industry leaders — myself included — have advocated for annual matching for early mover projects, with a shift to hourly matching over time once the industry reaches critical mass. Hourly matching isn’t practical or necessary for the earliest green hydrogen projects, and in fact could slow down green hydrogen adoption in key sectors and regions.

Those arguing for a rapid shift to hourly matching are relying on models where green hydrogen production “competes” with other demand for renewable electricity. If green hydrogen producers bought up a large share of the available renewable electricity, they argue, other users would be pushed to use fossil fuels, leading to higher emissions.

The MIT Energy Initiative looked at just this problem. They found that, for the near future, the renewable electricity demand from green hydrogen producers is likely to be relatively small compared to the amount of new renewable energy generation that is expected to be added to the grid each year. Today’s context more closely resembles a “non-compete” framework “in which low consequential emissions impacts with annual time-matching are likely,” the researchers found.

But hourly matching is not necessary in the short term. Annual time matching for first movers will effectively ensure minimal consequential emissions from green hydrogen production.

My company, Ambient Fuels, is a “pure-play” green hydrogen developer — it’s all we do. My team and I have spoken with hundreds of potential green hydrogen early adopters in industries facing the most complex decarbonization challenges. We see the impact of these policies in the real world.

As it stands, electrolyzers are still relatively expensive. Manufacturers are rushing to scale their production, but it’s going to take a few years for this new supply chain to materialize and for costs to come down. And the supply chain will only materialize if we have strong demand for green hydrogen. For now, much of the necessary infrastructure has yet to be built. These high initial costs mean that electrolyzers need to be run as close as possible to 100% capacity to spread the high up-front investment over a large quantity of hydrogen.

If an hourly matching system is implemented too soon, though, there won’t be enough credits available in certain hours. Electrolyzers will need to be run at a lower “capacity factor,” meaning that they won’t be able to produce as much hydrogen over a year. An even larger electrolyzer would be required to make the same amount of hydrogen, potentially driving up costs even further

A study from ACORE and E3 found that the cost of hydrogen production under an hourly matching system would be as much as 108% higher in the northern midwest (MISO) and 102% higher in Texas (ERCOT). Boston Consulting Group similarly found that early hourly matching requirements would more than double the cost of green hydrogen.

Current gray hydrogen users also need the supply of hydrogen to be continuous. To deliver consistent quantities of hydrogen under an hourly system will require either battery energy storage to ensure the electrolyzer can be run consistently, or large-scale hydrogen storage (in underground salt caverns) so that electrolyzers can scale up and down with the availability of credits.

RMI maintains that hourly matching could require up to twice the electrolyzer capacity and potentially five times the amount of hydrogen storage capacity to produce the same amount of hydrogen and deliver it with the same consistency as an annually matched system.

To control costs for green hydrogen and get the flywheel going for this nascent industry, the Treasury Department should apply a “start of construction” metric to determine the 2028 transition date so that 100% hourly time-matching is imposed only on projects that start construction after 2028 and are placed in service after 2032.

For projects placed in service before 2032, Treasury should consider adopting a formulaic approach in which first movers can meet a certain percentage of hourly matching for the tenure of the tax credit. A 70% hourly and 30% annual framework, for instance, could help balance the trade-offs.

Finding an equilibrium between practicality and perfection in the initial time-matching requirements will be essential to realizing the full potential of green hydrogen. Green hydrogen will play a key role in our zero-carbon future, but we can’t afford to delay. We need to start scaling now.

Jacob Susman is the CEO of Ambient Fuels, a green hydrogen company. The opinions represented in this contributed article are solely those of the author, and do not reflect the views of Latitude Media or any of its staff.